Engineered tubes can be designed based on the deformation profile of the expansion during hydroforming.

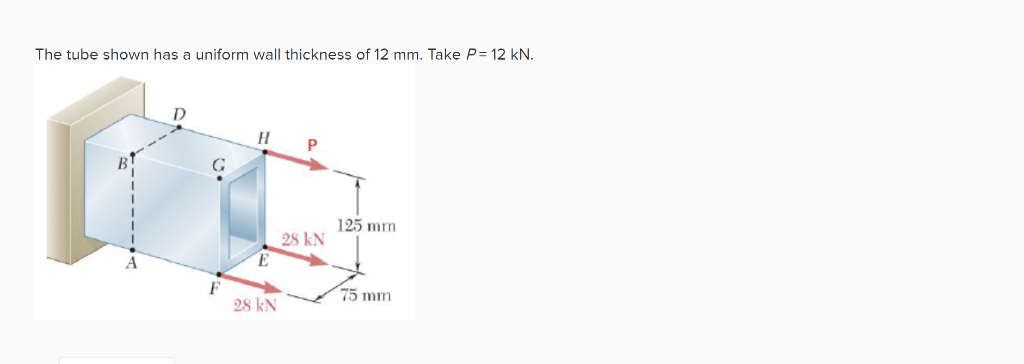

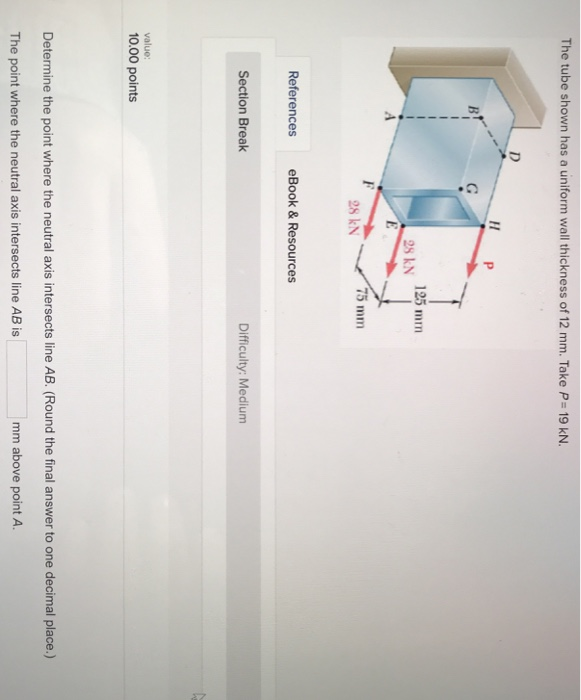

manufactures engineered aluminum tubes using a proprietary technique. 3Įngineered aluminum tubes commonly are used for manufacturing structural frames for bicycles. Tubes that have varying thickness circumferentially and an asymmetrical cross section also are called engineered tubes. Tubes with varying wall thickness along the length are known as butted or engineered tubes (see Figure 2). What Is An Engineered Tube?įigure 3 Engineered tube concept D has specific steps where the tube wall changes from constant thickness to increasing thickness. Two engineered tubes-those that appeared to provide the most uniform wall thickness in bulging-were selected and tested experimentally. Five engineered tube designs were analyzed by finite element analysis (FEA). This hydroforming study, which evaluated the formability limits of tapered tubes as compared to tubes of uniform wall thickness, includes both a description of the methodology used to evaluate various engineered tube designs and a comparison of simulation versus experimental results.

Figure 1(left) shows the deformation stages in the hydraulic bulge test, and the right side of Figure 1 shows that maximum thinning occurs at the center of the bulge. The tube is formed freely at the midsection (middle of the bulge). 2In this test, the tube is sealed at both ends and pressurized until it bursts. The hydraulic bulge test was used to investigate the wall thinning that occurs during hydroforming. The material is 6061 T4 aluminum OD = 64.135 mm, length = 230 mm, t o= 2.30 mm.įigure 2 A simple engineered tube has gradual changes in wall thickness. (Right) Measuring the tube's wall thickness along its length after bulging shows that the wall thinned from 2.30 mm to less than 1.85 mm at the bulge center. The most dramatic thinning is at the bulge center. 1įigure 1 (Left) An FEA model at intermediate stages of forming simulation of a uniform-thickness tube shows that the wall remains thick at the tube end but thins in the bulge area. Research conducted at the Engineering Research Center for Net Shape Manufacturing (ERC/NSM) examines the use of extruded aluminum tubes that vary in thickness both circumferentially and axially for these purposes. In such cases, other efforts are made to reduce wall thinning to produce a hydroformed component with nearly uniform wall thickness along its length. Often axial feeding is used to reduce wall thinning, but this is not always possible. Since the volume of tube material (the product of its cross section multiplied by its length) remains constant, the tube wall thins to accommodate the expansion. This effect was observed as far back as the mid-1800s, when it was found that trains passing in opposite directions tipped precariously toward one another.In tube hydroforming processes, tube is expanded by a high-pressure medium (usually water) until it fills a die cavity. The reason is the same: The high velocity of the air between the car and the truck creates a region of lower pressure between the vehicles, and they are pushed together by greater pressure on the outside ( (Figure)).

Similarly, when a car passes a truck on the highway, the two vehicles seem to pull toward each other. This pressure difference results in a net force, pushing the curtain inward. The reason is that the high-velocity stream of water and air creates a region of lower pressure inside the shower, whereas the pressure on the other side remains at the standard atmospheric pressure. For instance, shower curtains have a disagreeable habit of bulging into the shower stall when the shower is on. There are many common examples of pressure dropping in rapidly moving fluids. As a result, the pressure drops in a rapidly moving fluid whether or not the fluid is confined to a tube. The net work done increases the fluid’s kinetic energy.

0 kommentar(er)

0 kommentar(er)